Proper Substrate Preparation The Importance of Testing for Soluble Salts

The Gravel Truck Painting Example

Surface Prep & Soluble Salts

Ar-Tech was contacted by a local company to repaint a gravel truck dump box. While not a technically demanding project it was used to demonstrate the necessity of testing and treating for soluble salts such as chlorides prior to applying paint or coatings, even on blasted substrates. A white metal blast is unable to remove these types of contaminants and if left without additional surface prep (in this instance a standard SSPC-SP1 solvent clean) the corrosion cells will rapidly return and cause deterioration in a newly applied paint or coating.

Application of SSPC-SP1 Surface Prep in instances of Soluble Salts

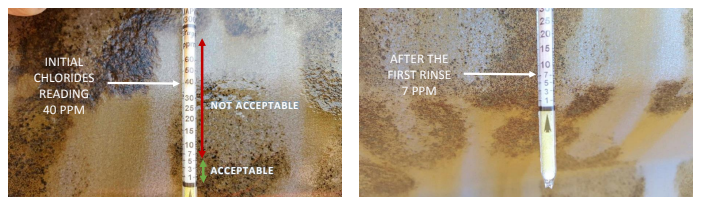

Soluble salts testing was conducted on the dump box for the presence of chlorides. The Kitigawa tube reading indicated 40 PPM (parts per million) of chlorides on the substrate. The most likely source of chlorides would be road salt. While there is currently no NACE or SSPC standard for testing for acceptable levels of soluble salts, most coating manufacturers will specify <5 PPM present on a substrate. Many products on the market can be employed using the SSPC-SP1 Solvent Cleaning standard to reduce or eliminate soluble salts. Some of these products can be applied right after blasting, prior to coating, eliminating additional blasting while other methods require a reblast after rinsing. Repeated rinses may be required to achieve acceptable levels. Concerns with coating adhesion to a treated surface are not an issue in instances where the products have been tested by their manufacturers. In the case of the gravel truck, the first rinse achieved chloride levels of 7 PPM. It took a 2 nd rinse to reduce the chlorides to an acceptable level of <5 PPM. Prior to painting the gravel truck dump box would receive a final blast to ensure a contaminant-free substrate with the optimal finish and profile for a long-lasting professional paint job.